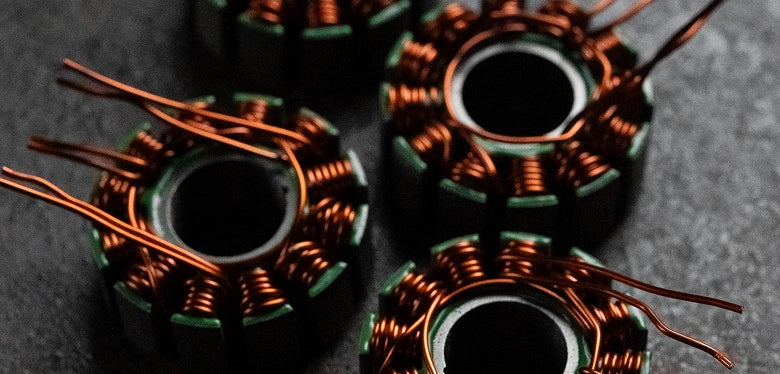

Quality motors for drones FPV_

Made in Ukraine.

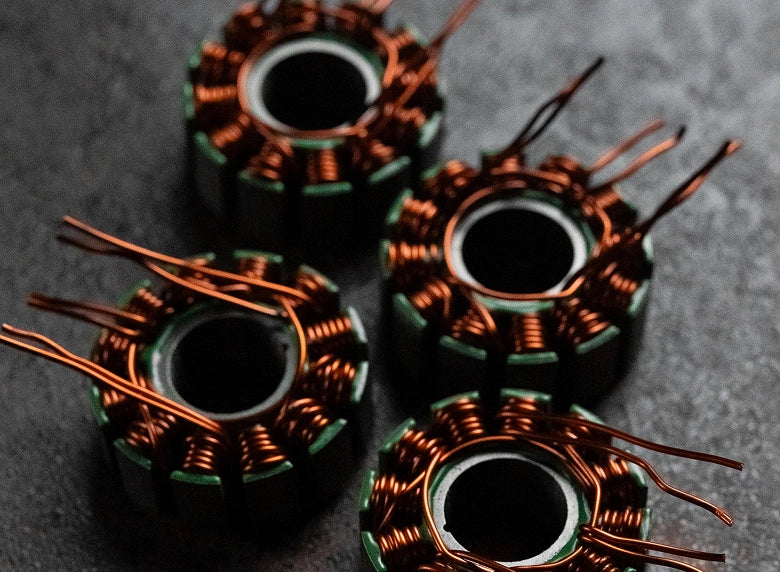

Quality motors for drones

Our products

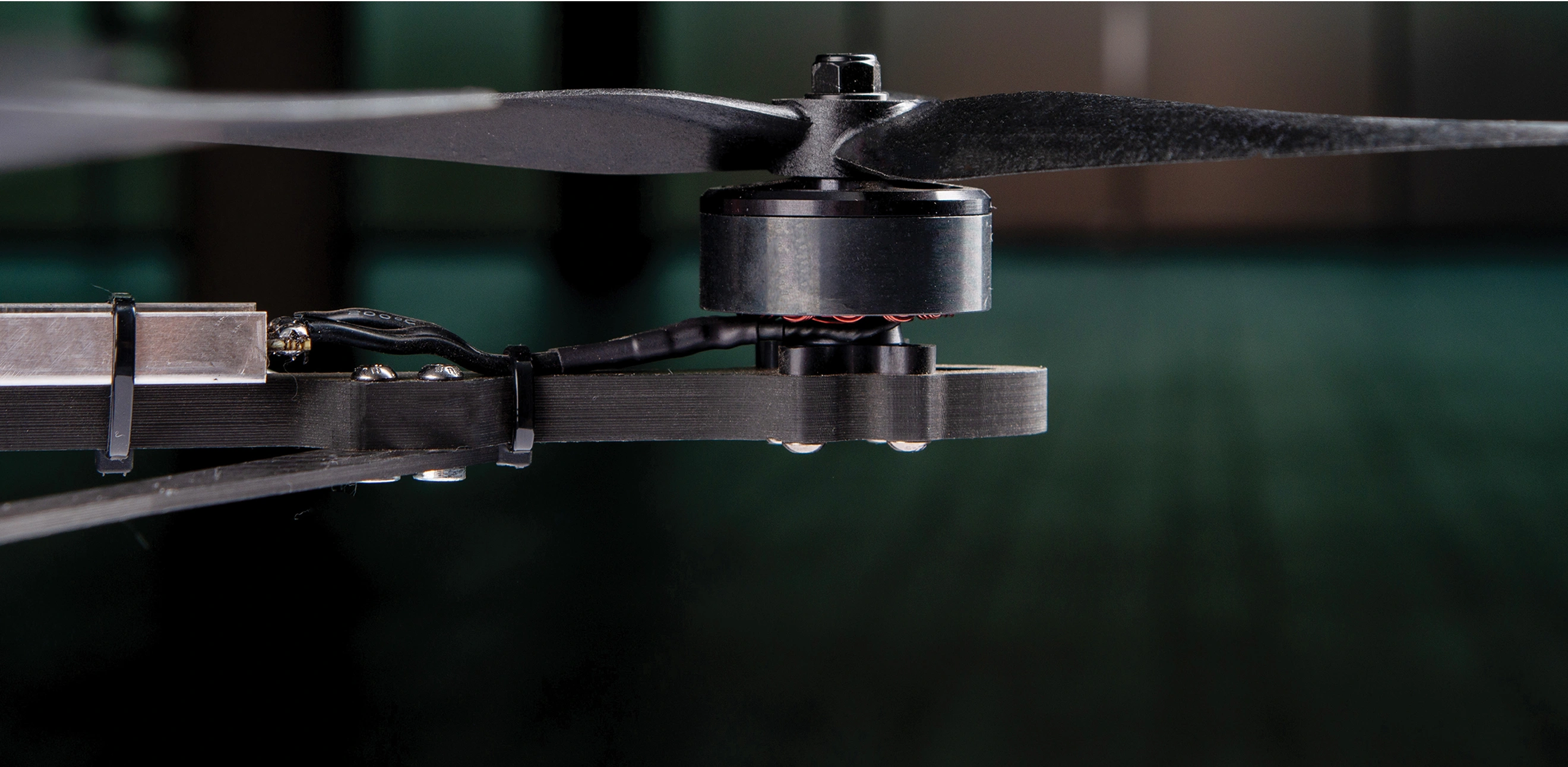

Our electric motors

created for efficient

logistics.

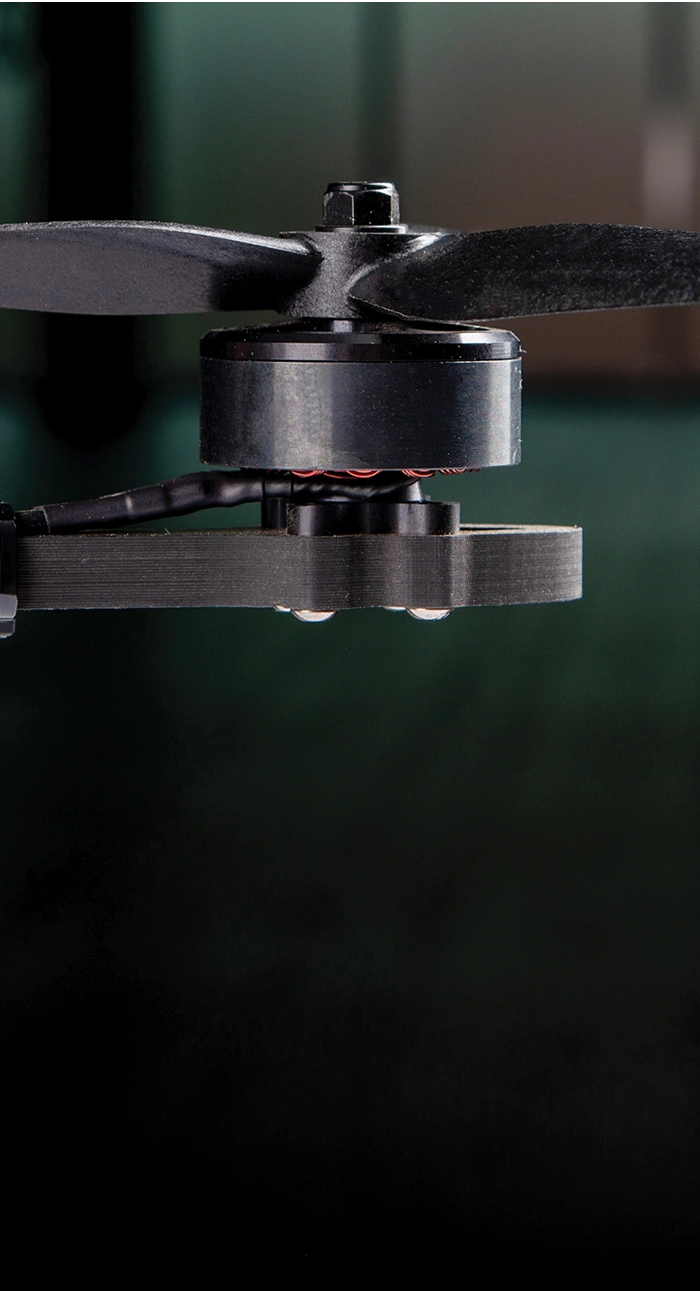

Ukrainian Motor-G electric motors are suitable for models of all form factors:

Motor-G electric motors have been delivering gifts since January 2024.

FVP

Heavy drones

Aircraft type

The Motor-G electric motor surpasses Chinese counterparts in all respects.

Propeller 1045

Similar products:

Technical support

Consult an expert to

to address your needs

Do you have a question?

Yes, our production is located directly in Ukraine. We try to achieve the highest possible level of localization, so we are constantly working on improving technology and expanding the list of elements that are manufactured in Ukraine.

Prices for the main types of motors are listed on our website. Please note that the cost of the product depends on the size of the order. So the larger the order, the lower the price. For wholesale orders (more than 4000 pcs at a time) special conditions are possible, which are discussed separately.

You can order our products through our website or by contacting the sales department using the contacts at the bottom of the page. For corporate clients, we also offer wholesale deliveries and individual terms of cooperation.

Yes, we have our own R&D department, so we can develop a motor for individual tasks, or help you choose something from existing solutions. Of course, choosing from existing solutions is a simpler task, because developing a new motor takes more than one month.

Of course, it all depends on the size of the batch and the type of motor. We try to maintain stock availability for the most popular models. If the order is small, we can fulfill it within a few days. If it is a wholesale long-term order, the delivery terms should be discussed with our sales department. We have built the production according to the Lean Manufacturing principle, so you will not have to wait until we finish the production of the entire batch, because we can make shipments gradually, as production progresses.

The productivity of our enterprise is constantly growing. You can check the current capacity with our managers.

Yes, this is one of our advantages as a local manufacturer. We will help you choose a motor for your setup (propeller, battery, drone weight and speed), produce test samples with non-standard KV, prepare test reports, etc.

Product quality is our special pride. Each motor goes through at least 5 stages of inspection before shipment, so you can be confident in the quality of our motors. Even if something goes wrong, we can quickly react to the situation and make the necessary changes.

Form

reverse

communication

Remaining

question?